Anaphora

In order to facilitate the Research & Development engineers to find the silicone wire specifications , 《Common electronic wire Specifications 》.

This standard is one of the series standards of design technical standard system , that Product Research & Development center of our company .

References in this standard :

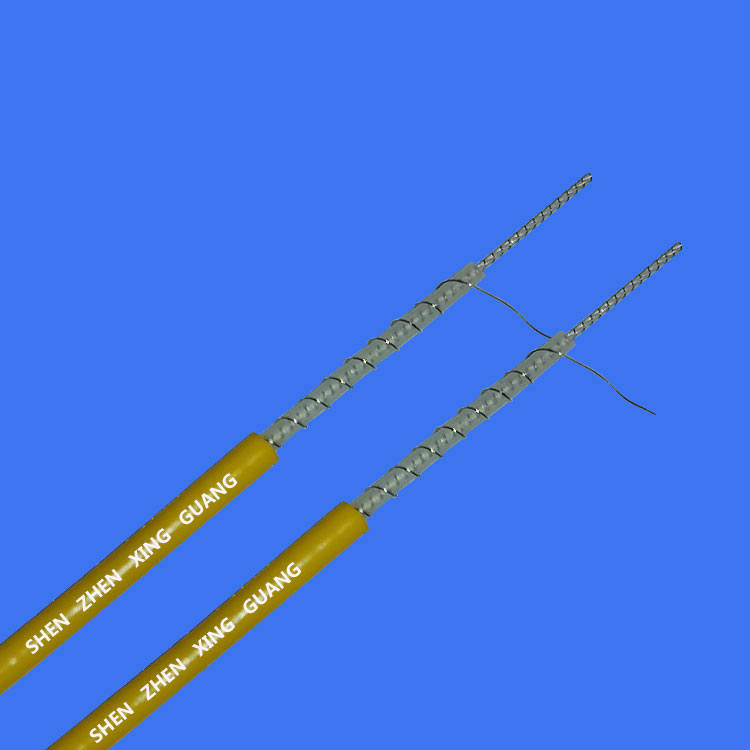

-《Common Wire Number & Section Dimensions》 is provided by Shenzhen XingGuang Electric Heating Products Co., LTD.

-《Common Electronic Wire Code & Related Parameters》is provided by Shenzhen XingGuang Electric Heating Products Co., LTD.

Appendix 《Minimum Cross-sectional Area of Conductors》

This standard is proposed by the standardization project team of Product Research & Development Center.

The main draftsman of this standard : 2015-11-25

Approver of this standard :

1、Subject content and scope of application:

This standard specifies the electronic wire specification number and related parameters.

This standard applies to controlled drawings , engineering BOM and other technical documents.

2、Common line specification number and section size:

Wire gauge AWG (American wire gauge) | diameter(mm) | area(mm2) |

10 | 2.588 | 5.262 |

11 | 2.305 | 4.172 |

12 | 2.053 | 3.309 |

13 | 1.828 | 2.624 |

14 | 1.628 | 2.081 |

15 | 1.450 | 1.650 |

16 | 1.291 | 1.309 |

17 | 1.150 | 1.037 |

18 | 1.024 | 0.8226 |

19 | 0.912 | 0.6529 |

20 | 0.812 | 0.5174 |

21 | 0.723 | 0.4105 |

22 | 0.644 | 0.3256 |

23 | 0.573 | 0.2581 |

24 | 0.511 | 0.2047 |

25 | 0.455 | 0.1623 |

26 | 0.405 | 0.1288 |

27 | 0.361 | 0.1021 |

28 | 0.321 | 0.08097 |

29 | 0.286 | 0.06422 |

30 | 0.255 | 0.05097 |

31 | 0.227 | 0.04039 |

3、Commonly used electronic line number and related parameters

Number | UL number | Temperature resistance(℃) | Rated voltage(V) | Insulation materials | Test voltage(V) |

1 | 1007 | 80 | 300 | PVC |

|

2 | 1015 | 105 | 600 | PVC |

|

3 | 1332 | 200 | 300 | Teflon | 2500 |

4 | 10362 | 250 | 600 | Teflon | 2500 |

5 | 1815 | 250 | 300 | Teflon | 4000 |

6 | 3122 | 200 | 300 | Silicone rubber (inner), glass fiber woven (outer) | 1500 |

7 | 3239 | 150 | 300/600/10000 | silicon rubber | 6000/25000 |

8 | 3135 | 200 | 600 | silicon rubber | 2000 |

Note: Temperature data for reference.

Appendix A

(Information Appendix)

A. 1 Minimum cross-sectional area of A conductor:

Rated current of the appliance(A) | Nominal cross-sectional area(mm2) |

≤0.2 | Foil wire a |

>0.2 and ≤3 | 0.5a |

>3 and ≤6 | 0.75 |

>6 and ≤10 | 1(0.75)b |

>10 and ≤16 | 1.5(1.0)b |

>16 and ≤25 | 2.5 |

>25 and ≤32 | 4 |

>32 and ≤40 | 6 |

>40 and ≤63 | 10 |

Footnote a: It can be used only when the exposed length of the power cord does not exceed 2m.

Footnote b: For portable appliances , if the length of the power cord does not exceed 2m , the cross-sectional area of the power cord can be used as the value in brackets ( portable appliances: not weighing more than 18kg and movable ).